For all concreting jobs Crack-A-Joint will allow you to pour more by not having to worry about sawcutting. Crack-A-Joint is ideal for concreting where controlled cracking is specified

ADVANTAGES OF CRACK A JOINT

-

IMMEDIATE ACTION - Crack-A-Joint induces crack immediately because of its method of application.

-

FINISH FLOOR SAME DAY - No need to return to finish off.

-

NO CUTTING OF MESH - Crack-A-Joint means no cutting of mesh, to ensure crack enducing. This ensures cracks are kept to a minimum.

-

ABSOLUTELY NO WASTAGE.

-

ANY GIVEN EDGE - Crack-A-Joint will butt up to any given edge. Eg. columns.

-

PRECISE - Crack-A-Joint takes the uncertainty and guess work out of precise surface crack controlling.

-

RIGID - During installation, Crack-A-Joint remains rigid.

-

INTERLOCKING - Because of Crack-A-Joint's shape, it makes it almost impossible to be dislodged.

-

CLEAN AND QUICK - Crack-A-Joint is quick clean and no mess to clean up.

-

POSITIVE ALTERNATIVE - Crack-A-Joint now gives the building industry a positive alternative to sawcutting.

-

CAPPING - Interlock capping available for specified fill and exposed concrete.

-

NO FILL REQUIRED - Crack-A-Joint's Rip-A-Strip capping provides the joint sealant.

-

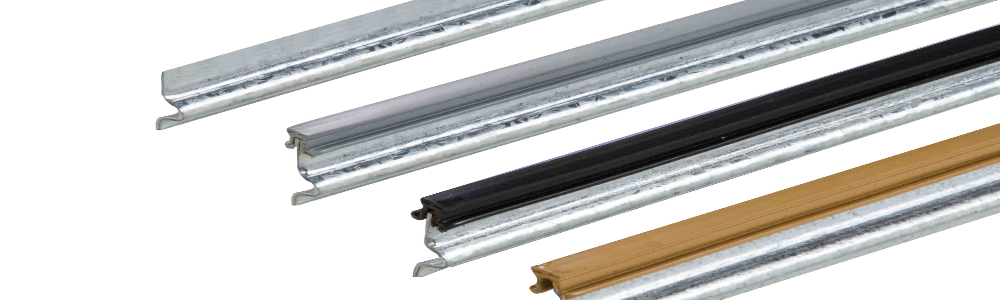

RIP-A-STRIP AVAILABLE IN 4 COLOURS.

GALVABOND ARCHITECTURAL AND ENGINEERING SPECIFICATIONS

-

A galvanised, mild steel strip, 1.2mm thick

-

Designed for on ground slabs

-

Assures the controlling and reducing surface crazing and cracking

-

Specifically designed to be placed while concrete is wet

-

Shape of Crack-A-Joint makes it almost impossible to be dislodged

-

Enables continuity and the maximum strength of mesh and steel

-

Depth of Crack-A-Joint is equal to or about 1/4 depth of concrete slab

-

Permanent interlock capping.

WEATHER CONDITIONS

Change in weather condition can send concrete off before finishing is complete. Crack-A-Joint placed before concrete sets will save valuable time for concretors and improves overall finish.

DOUBLE ACTION CRACK-A-JOINT

Double action Crack-A-Joint has two major features. Firstly it controls surface cracking when placed while screeding. Second by not cutting mesh, continuity is obtained and the risk of excessive cracking is minimized.

CRACK-A-JOINT INTERLOCK CAPPING

Thermoplastic Interlock Capping has the environmental resistance of general purpose E.P.D.M. rubber, with the fluid resistance and flexibility comparable to neoprene and rubber. Crack-A-Joint "Interlock Capping" prevents dust and grit penetrating the joint.