ESSENTIAL

Under seismic conditions, Lesa Bearing Strips, placed under the ends of precast hollowcore floor units, are vitally important - as described below.

SEISMIC CONDITIONS

Research undertaken in New Zealand by the University of Canterbury has demonstrated that, under seismic drift during earthquakes, serious structural problems can occur with hollowcore precast floor units, unless special provision is made in the seating and attachment. This research has resulted in revisions to the New Zealand Design Codes.

Specifically, the hollowcore units must be seated on a low friction bearing strip. This allows movement between the hollowcore unit and the beam when inter-storey drift occurs. Without this movement, failure of the hollowcore units can occur. In a severe earthquake, this failure can be catastrophic.

HOW

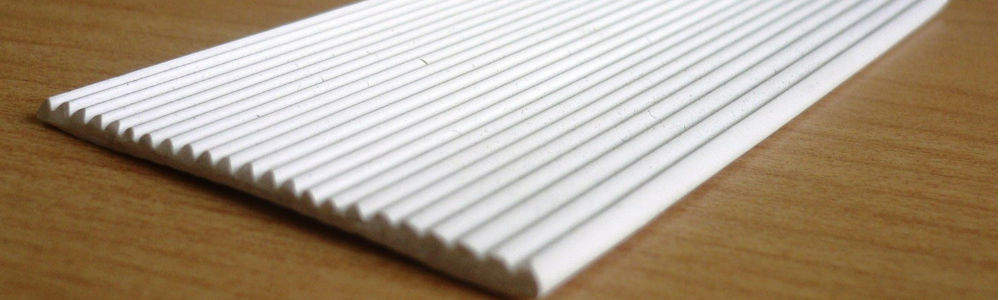

Lesa Bearing Strips are co-extruded PVC plastic strips with a hard smooth upper surface, and a lower surface which incorporates three continuous, soft, high friction ribs. The ribbed surface is placed face down on to the insitu bearing surface (beam, ledge or wall) where the soft ribs will grip against that surface. A mortar bedding may be necessary to give a level surface on which the bearing strip is seated. The precast hollowcore units are then placed on the smooth top surface of the bearing surface.

During seismic movement, the hollowcore unit can slide on the smooth top surface of the bearing strip, while the ribs of the bearing strip hold it in place.

PRODUCT SPECIFICATION, DIRECTIONS FOR USE

| Dimensions: |

55mm x 3mm x 2.4 metres long. |

| Material: |

Durable, ABS plastic. |

| Cutting to length: |

Score with a knife or similar and snap. |

| Installation: |

Place ribbed surface face down on to level, uniform bearing surface (beam, ledge, top of wall), in positions shown on sketches.

If needed, use contact adhesive or tape to hold bearing strip in position while precast units are placed. Place precast units directly on to bearing strips. |