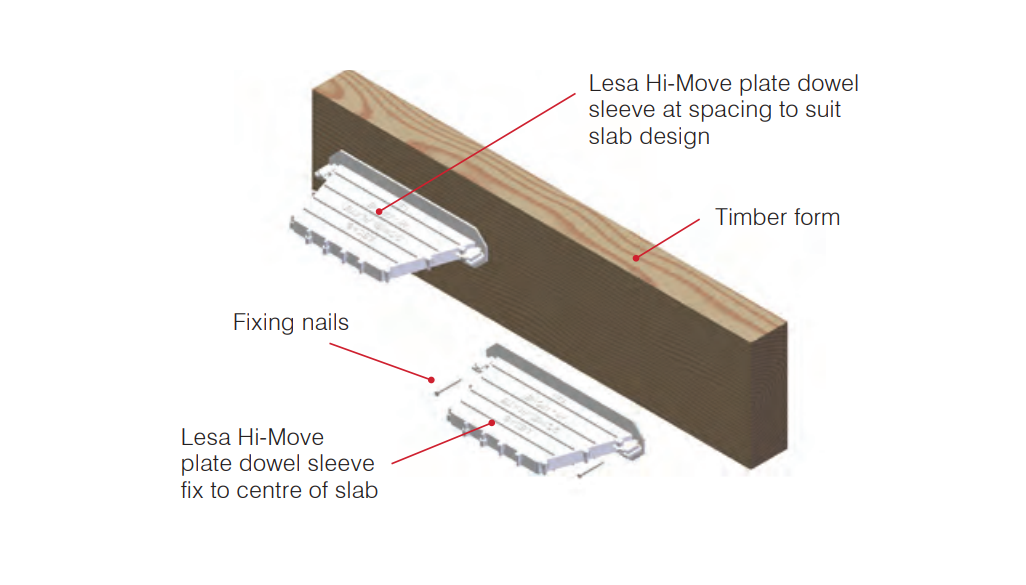

The Hi-Move plate dowel system enables this unique sleeve to be cast into new slabs without having to penetrate formwork, thus eliminating damage to the forms. The built-in ring shank nails make installation quick and easy and also ensure accurate dowel alignment.

This is achieved by the sleeve generating a precise void in the concrete into which the dowel plate can be inserted at the optimum time of construction. The parallel sided steel plate ensures constant bearing at all times while the tapered sleeve allows progressive lateral movement as the concrete shrinks and cures.

The construction of the sleeve is such that it ensures once the dowel plate is inserted into the sleeve an effective seal is formed around the dowel to prevent concrete slurry from entering the sleeve.

Note: For additional lateral movement requirements, two sleeves can be used, back to back. This is an important issue that is often over-looked when on-site fabrication of dowel sleeves using oversized conduit is used.

Hi-Move plate dowels are available in black steel, stainless steel, or hot-dip galvanised. For spacing of Hi-Move plate dowels, please contact Lesa Systems.